Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile sheet metal. Commonly used equipment includes box and pan brakes, brake presses, and other specialized machine presses.

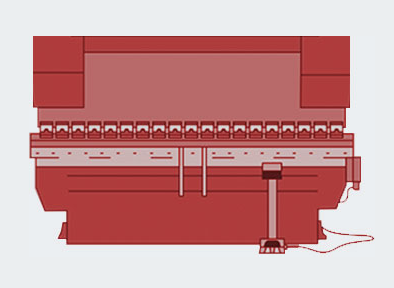

1. In a press brake, sheet metal is held in place by clamps between a matching punch and die, and the machine’s ram, with punch attached, moves downward to form a predetermined bend.

2. A folding machine relies on a swinging beam that folds the sheet metal, which is positioned and held by clamping beam tools.

3. In sheet metal bending, the sheet metal is positioned below blank-holder tools, which descend and clamp it in place, with material protruding on the other side; the machine’s bending blades from above and below move to fold the metal.

4. Follow-up operations are often used to finish the sheet metal parts.

You could choose aluminum, brass, copper, steel, tin, nickel and titanium etc. For decorative uses, important sheet metals include silver, gold, and platinum etc.

Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication.

Auto parts, medical devices, home appliances, robotics, scientific instruments etc.

Maintain consistent part quality and guaranteed lead times under our one-stop service.

| Materials | Material Category | Attributes / Applications |

|---|---|---|

| Carbon Steel | Metal | / |

| 304 Stainless Steel | Metal | / |

| 316 Stainless Steel | Metal | / |

| Aluminum Alloys – 2017 | Metal | / |

| Aluminum Alloys – 5052 | Metal | / |

| Aluminum Alloys – 6061 | Metal | / |

| Aluminum Alloys – 6063 | Metal | / |

| Aluminum Alloys – 6082 | Metal | / |

For more specific materials, please feel free to contact our engineers.

After machining, surface finishes are applied and customers can select the appearance, surface roughness, hardness and chemical resistance of the finished parts as they like. What surface finishing can I get? Click Here

High Precision Full CMM inspection to guarantee the high precision of the products