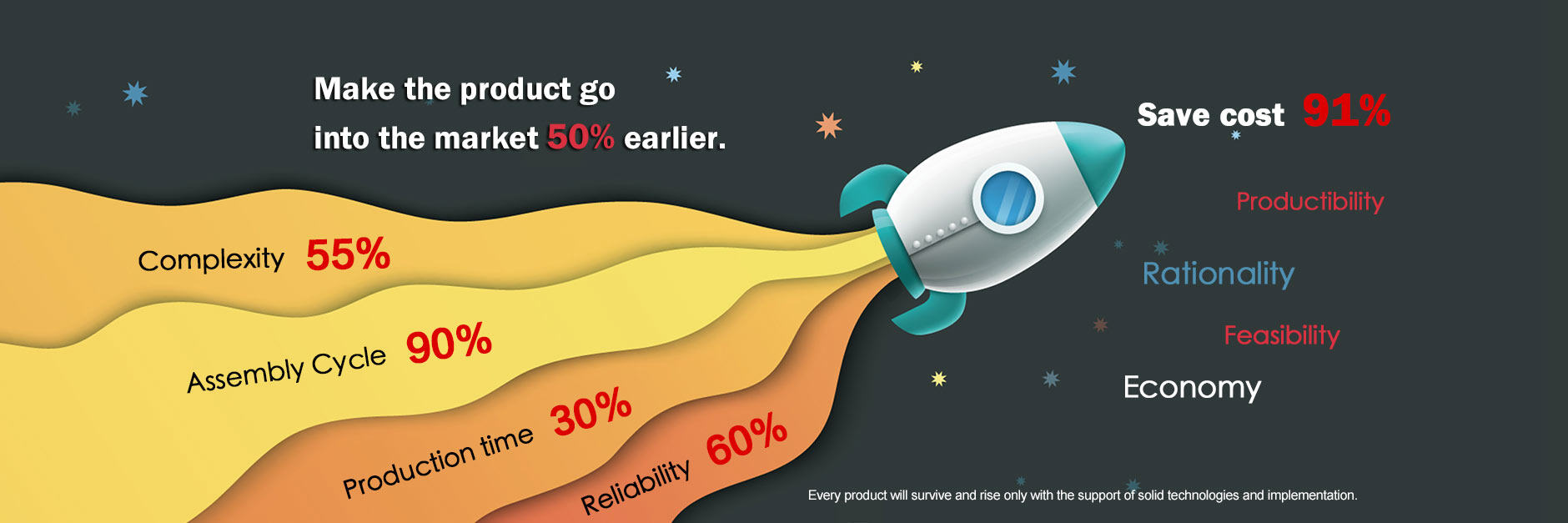

Design for manufacturing (also sometimes known as design for manufacturability or DFM) is the general engineering practice of designing products in such a way that they are easy to manufacture. At RPWORLD, our professional DFM service describes the process of designing or engineering a product in order to facilitate the manufacturing process with the purpose of reducing manufacturing costs, accelerating production time and improving products quality.

Professional Sales Support Engineer Team

servingall our clientsto optimize theirdesigns

formanufactur ability and assemblability

Significative proposals through the entire project

cycle, not only solving the current problems,

but also paying more attention to subsequent

batches production and mass production,

which could help customers save time.

Rich projects and processing experence

to help customers avoid risks effectively

from the source.

Consistent recommendationsof the most

suitable solution to help customers save costs.

Click here to know how RPWORLD help you on DFMA to reduce parts cost and save production time.

RPWORLD supports a fast developing medical company in Europe from prototype to customized production for the high class eye diagnostics device…

DFMA is designed to ensure product design at lower cost, shorter time and higher quality by improving product manufacturability and assimilability on the premise of taking product …

The client asked for design with no screws, so we chose clips, however, the clip hook was broken during drop testing, what should we do?Learn how to design proper clips…

INNORAPID LIMITED, with brand RPWORLD® established in year 2003, has developed to be a world famous…