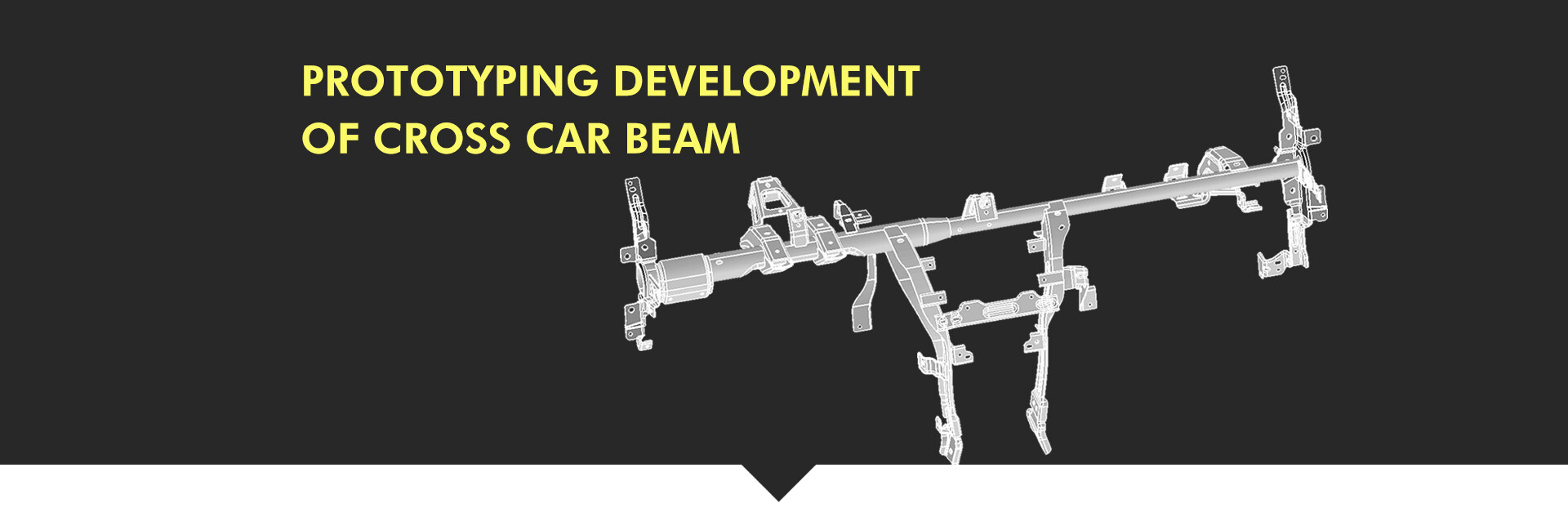

The Cross Car Beam (CCB) is a component located in the front of the vehicle under the instrument panel (IP). It is normally designed to support the steering column, airbags, and instrument panel. Aside from its support role, this component is instrumental in providing a greater strength and control of the steering wheel.

The client is a well-known automotive company. Mass production problems caused a delay of the Cross Car Beam (CCB) during R&D process, the mass production supplier could not provide 47 sets CCB as planned. But assembly of the prototype vehicle had to begin within one month. As a long-term strategic partner, we were asked to help the client to solve the problem.

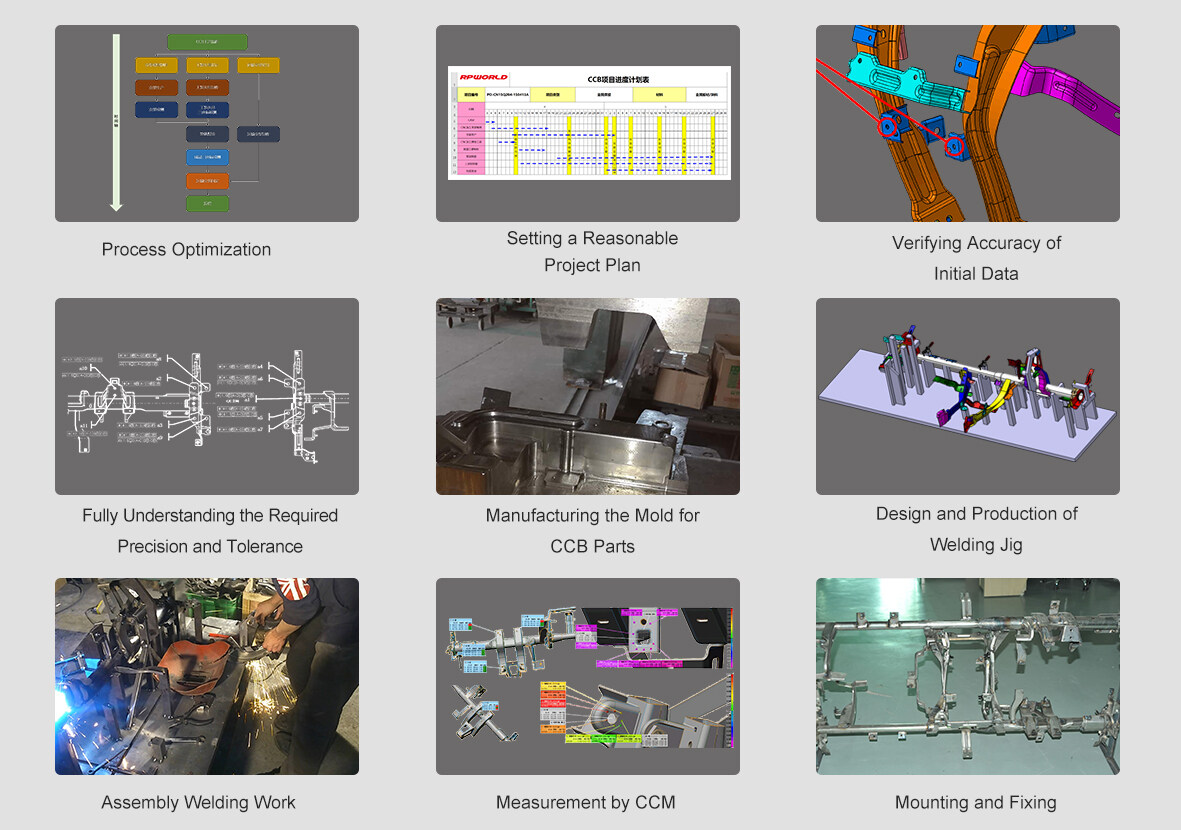

◆ Verify the installation points between beam and body-in-white

◆ Ensure the assembly of beam, instrument panel and other parts

◆ Simulate the strength of material performance

◆ Precision of various holders and the complete welded body

◆ Tight schedule

After-sales service mainly included on-spot assistance to engineers with feedback, analysis, modifications and processing.

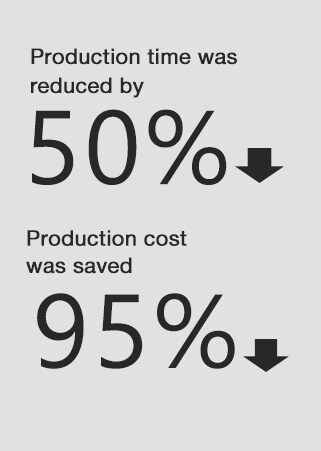

◆ Production time was reduced by 50%

◆ Production cost was saved 95% compared with traditional mass production solution

◆ After 6 months, the client told me that what we did produced using rapid sheet-metal process resulted in better accuracy than the samples from mass production factories

The high level of success of the CCB project, is mainly a result of our teamwork and deep understanding of project. In my mind, not only do we supply high-quality products and outstanding services, but also we deliver even beyond stated commitment to clients; as per one of our core values: Under promise over deliver.