You want your parts to look and feel exactly as you designed them to, so achieving the perfect surface finish is essential to your complete satisfaction. RPWORLD supply a full range of services, from anodizing to painting, plating, printing, laser and handmade, all with the most careful attention to detail. See how we ensure beautiful parts by different surface treatment or contact us to get your free quote.

The quality of the surface treatment determines the value and ultimately the success of a product. That’s why we go the extra mile. RPWORLD offers a variety of surface finishes to meet the customer requirements. Here is case for you to know more about how RPWORLD surface treatment let your parts as exactly as design.

Use RPWORLD as your one-stop solution for both manufacturing and surface finishing of your custom machined parts, reducing the risk of production.

| Picture | Name | Description | |

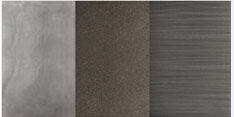

| Texture |  | MT Texture | Mold Texture is also known as Grain. It refers to rough surface finish, the other one is called Gloss Finish. |

| VDI Texture | Verein Deutscher Ingenieure, the Association of German Engineers. | |

| RPPTC Texture (01-08) | RPWORLD supply our own texture for your choose. | |

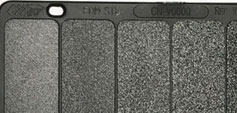

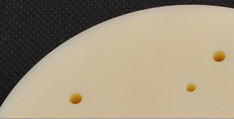

| Transparency |  | RP-Translucency 10% | Different levels of transparency can be provided, transparency 10% is shown in the picture. |

| RP-Translucency 30% | Different levels of transparency can be provided, transparency 30% is shown in the picture. | |

| RP-Translucency 50% | Different levels of transparency can be provided, transparency 50% is shown in the picture. | |

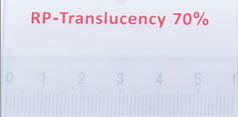

| RP-Translucency 70% | Different levels of transparency can be provided, transparency 70% is shown in the picture. | |

| RP-Translucency 90% | Different levels of transparency can be provided, transparency 90% is shown in the picture. | |

| RP-Translucency 100% | Different levels of transparency can be provided, transparency 100% is shown in the picture. |

| Picture | Name | Description | |

| Painting |  | Normal | A spray gun is used to disperse the paint droplets by means of air pressure and applied to the surface of the object to be coated. |

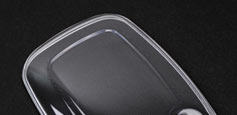

| Transparency | A spray gun is used to disperse the paint droplets by means of air pressure and applied to the surface of the object to be coated. | |

| Caoutchouc | A spray gun is used to disperse the paint droplets by means of air pressure and applied to the surface of the object to be coated. | |

| EMC Coating | A spray gun is used to disperse the paint droplets by means of air pressure and applied to the surface of the object to be coated. | |

| Metallic | A spray gun is used to disperse the paint droplets by means of air pressure and applied to the surface of the object to be coated. | |

| Anodizing |  | Nature | Anodizing can create a thin, hard, non-conductive ceramic coating on the surface of aluminum parts to strengthen their corrosion and wear resistance. It’s available for different colors. |

| Color | Anodizing can create a thin, hard, non-conductive ceramic coating on the surface of aluminum parts to strengthen their corrosion and wear resistance. It’s available for different colors. | |

| Hardcoat | Hardcoat anodizing generates a thicker ceramic coating to provide excellent corrosion and wear resistance for functional applications. | |

| Plating |  | Galvanic Plating | It is the process of plating a thin layer of other metals or alloys on certain metal surfaces by electrolysis to prevent metal oxidation, improve wear resistance, electrical conductivity, light reflectivity, corrosion resistance and enhance the appearance of beauty. |

| Ion plating | It is the process of plating a thin layer of other metals or alloys on certain metal surfaces by electrolysis to prevent metal oxidation, improve wear resistance, electrical conductivity, light reflectivity, corrosion resistance and enhance the appearance of beauty. | |

| Printing |  | Silk Printing | During printing, the ink is transferred to the substrate through the mesh of the graphic portion by the extrusion of the squeegee to form the same graphic as the original. Its equipment is simple, easy to operate, simple in printing, low in cost, and strong in adaptability. |

| Pad Printing | It is capable of printing text, graphics and images on the surface of irregular shaped objects. | |

| Roller Printing | / | |

| Laser |  | Laser | No contact with the surface of the material, no mechanical movement, no deformation of the surface, generally no need to fix. High processing precision, fast speed and wide application fields. |

| Handmade |  | Smoothing | In order to achieve a surface roughness, parts are machined at a lower feed rate. Surface roughness can be changed comparatively upon request. |

| Brushing | It forms lines on the surface of the work piece by grinding to provide a decorative effect. Since it can reflect the texture of the metal material, it has been more and more widely used. | |

| Polishing | It reduces the surface roughness of a workpiece by mechanical, chemical or electrochemical action to obtain a bright and smooth surface. It is done by using polishing tools and abrasive particles or other polishing media. | |

| Sand Blasting/ Shot Blasting | Bead blasting can make a uniform matte or satin surface finish on the machined parts to remove all tool marks. It’s mainly applied for aesthetic purposes. | |

| Others |  | Water Transfer Printing | Water Transfer Printing is the process of applying decorative finished to 3D products. Any hard surface, non-porous and that can be submersed in water can be decorated. Another good rule of thumb is if you can get paint to stick to the object most likely you can decorate it with this process. |

| Color Printing | Color printing is the reproduction of an image or text in color (as opposed to simpler black and white or monochrome printing). |

For more surface treatment requirements, please click here to contact us or send email to info@rpworld.com

After machining, surface finishes are applied and customers can select the appearance, surface roughness, hardness and chemical resistance of the finished parts as they like. What surface finishing can I get? Click Here

High Precision Full CMM inspection to guarantee the high precision of the products