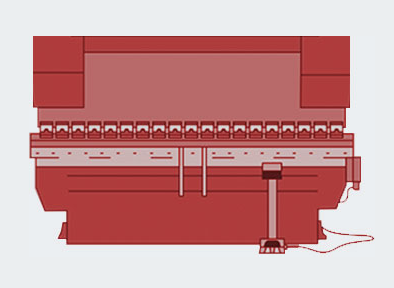

Stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the sheet metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging and coining etc.

● Bending – the sheet metal is deformed or bent along a straight line.

● Flanging – the sheet metal is bent along a curved line.

● Embossing – the sheet metal is stretched into a shallow depression. Used primarily for adding decorative patterns.

● Blanking – a piece is cut out of sheet metal, usually to make a blank for further processing.

● Coining – a pattern is compressed or squeezed into the sheet metal. Traditionally used to make coins.

You could choose aluminum, brass, copper, steel, tin, nickel and titanium etc. For decorative uses, important sheet metals include silver, gold, and platinum etc.

Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication.

Auto parts, medical devices, home appliances, robotics, scientific instruments etc.

Maintain consistent part quality and guaranteed lead times under our one-stop service.

| Materials | Material Category | Attributes / Applications |

|---|---|---|

| Carbon Steel | Metal | / |

| 304 Stainless Steel | Metal | / |

| 316 Stainless Steel | Metal | / |

| Aluminum Alloys – 2017 | Metal | / |

| Aluminum Alloys – 5052 | Metal | / |

| Aluminum Alloys – 6061 | Metal | / |

| Aluminum Alloys – 6063 | Metal | / |

| Aluminum Alloys – 6082 | Metal | / |

For more specific materials, please feel free to contact our engineers.

After machining, surface finishes are applied and customers can select the appearance, surface roughness, hardness and chemical resistance of the finished parts as they like. What surface finishing can I get? Click Here

High Precision Full CMM inspection to guarantee the high precision of the products