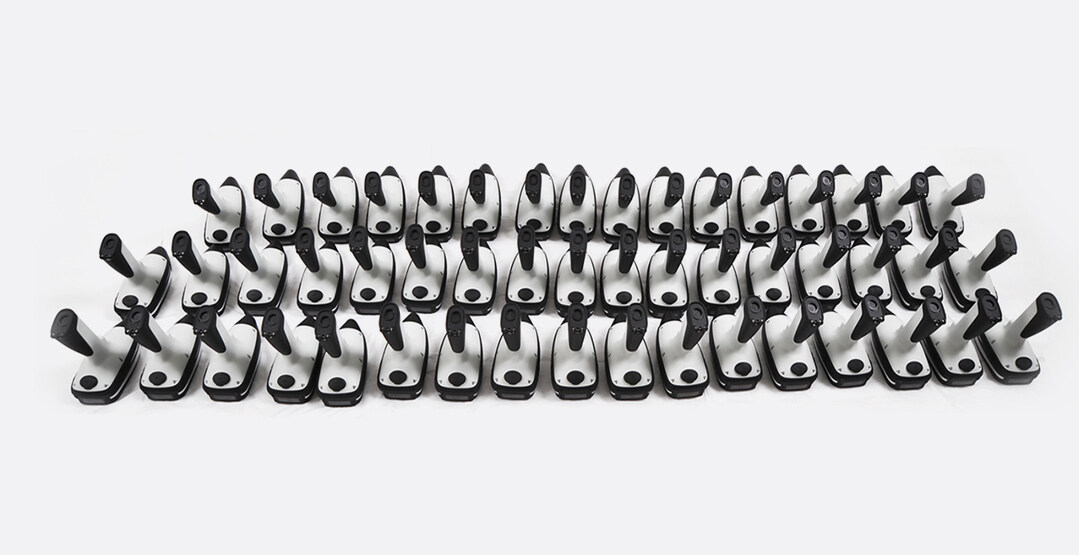

A company well-known for superior analytical instruments and laboratory equipment opted for RPWORLD to produce 100 units assembly parts of a Spectrometer per order, the total demand is 400 sets per year.

★ How to select the most suitable manufacturing processes to meet the customer’s requirements?

★ How to achieve the good surface effect and mechanical performance for the products?

★ How to guarantee high quality and meet client’s tight deadline?

Processes Chosen

• After meticulous analysis and discussion, we chose vacuum casting combined with over-molding process, for the metal parts, we use CNC machining and sheet metal process.

• Internal copper painting for EMC.

Material Selection

• ABS performance Polyurethane Resin, PC,TPE

• Rubber to be over-molded

• Stainless steel, aluminum

| • Rapid prototyping and testing | 7 days |

| • Silicon mold manufacturing and testing | 3 days |

| • 100 units replication by urethane casting | 15 days |

| • After-treatment by specialist | 5 days |

| • Total | 30 days |

√ Lead time was reduced by 50%, 100 units were delivered in 30 days.

√ Production cost was 70%~80% less than traditional tooling solution.

√ All the production, after-treatment and pre-assembly were done by only one suppli er -RPWORLD, which greatly reduced project risks.

√ Close communication and professional coordination ability ensured the high quality and on-time product launching.

√ Long-term product development partnership with RPWORLD established.